Lampson’s Manitowoc 4600 Ringer and 4100 assemble 2 x Reclaimer machines.

Increasing efficiency – building 2 x Reclaimers with 1 x M4600Ringer and 4100.

The Manitowoc 18000 Max-er makes this Reclaimer assembly look easy.

2 x Lampson Transi-Lift cranes install conveyor gantry sections at the Wiggins Island Coal Export Terminal (WICET) project in QLD.

Lampson Transi-Lift, the LTL-2600, prepares to lift the precipitator at Nyrstar’s Port Pirie Lead Smelter, South Australia.

The Manitowoc 16000 lifting a mill in the confines of an Aluminium Refinery.

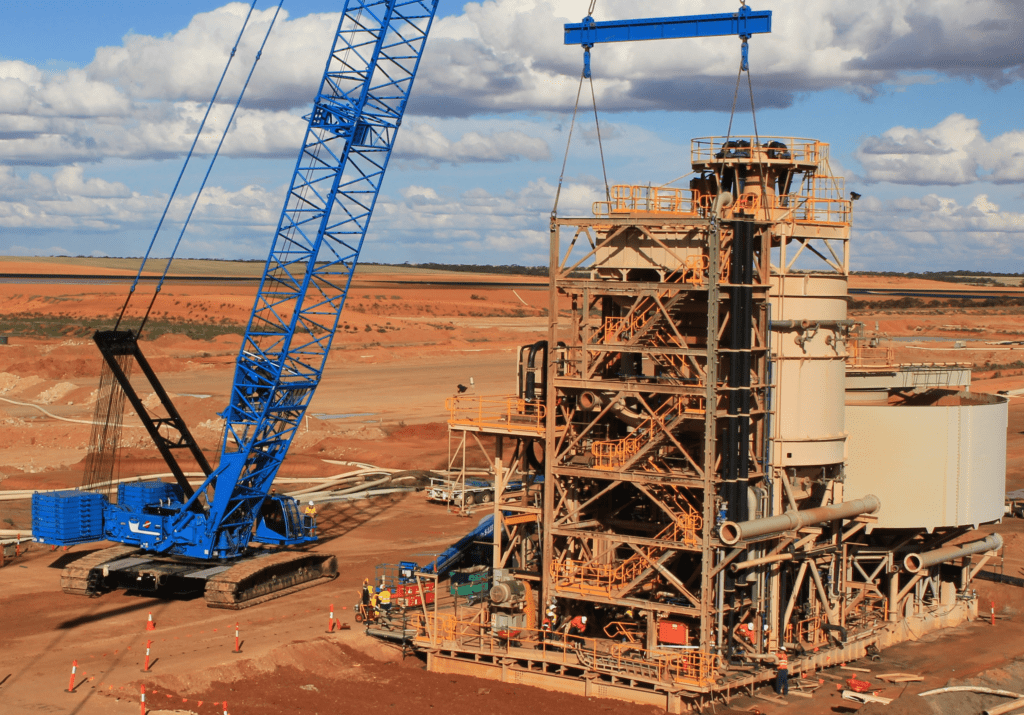

Lampson’s Manitowoc 18000 installing modules of the crushing station at Roy Hill.

Sand Mining plant relocation at Ouyen VIC with the help of a Manitowoc 16000.

Lampson’s Manitowoc 4100 Ringer ready to start work on a coal mine vent shaft.